Lean manufacturing is a systematic approach to manufacturing that focuses on minimizing waste and maximizing value for the customer. It is based on the idea that anything that does not add value to the product or service is considered a waste of time, effort and resources.

Some of the most successful companies in the world, including Toyota, Nike, and General Electric, use lean manufacturing principles. By implementing lean manufacturing principles into your maintenance and reliability operations, you can develop a more streamlined and efficient process.

What is Lean Manufacturing?

In the most simple of terms, lean manufacturing is a methodology that aims to eliminate all waste at all stages of the production chain—a way to do more with less, while moving closer to providing improved customer satisfaction.

It is similar to Total Productive Maintenance (TPM), and shares some fundamental concepts like the 5S principle, autonomous and planned maintenance, and continuous improvement to optimize maintenance operations.

The concept was initially started in Japan by Toyota employee, Taiichi Ohno, (and is often considered as a development of “TPS – Toyota Production System”), with the specific industry term “Lean” being coined in 1988 by American businessman John Krafcikby, and defined by Professor James Womack from MIT, US, in the early 1990s.

What are the 5 principles of lean?

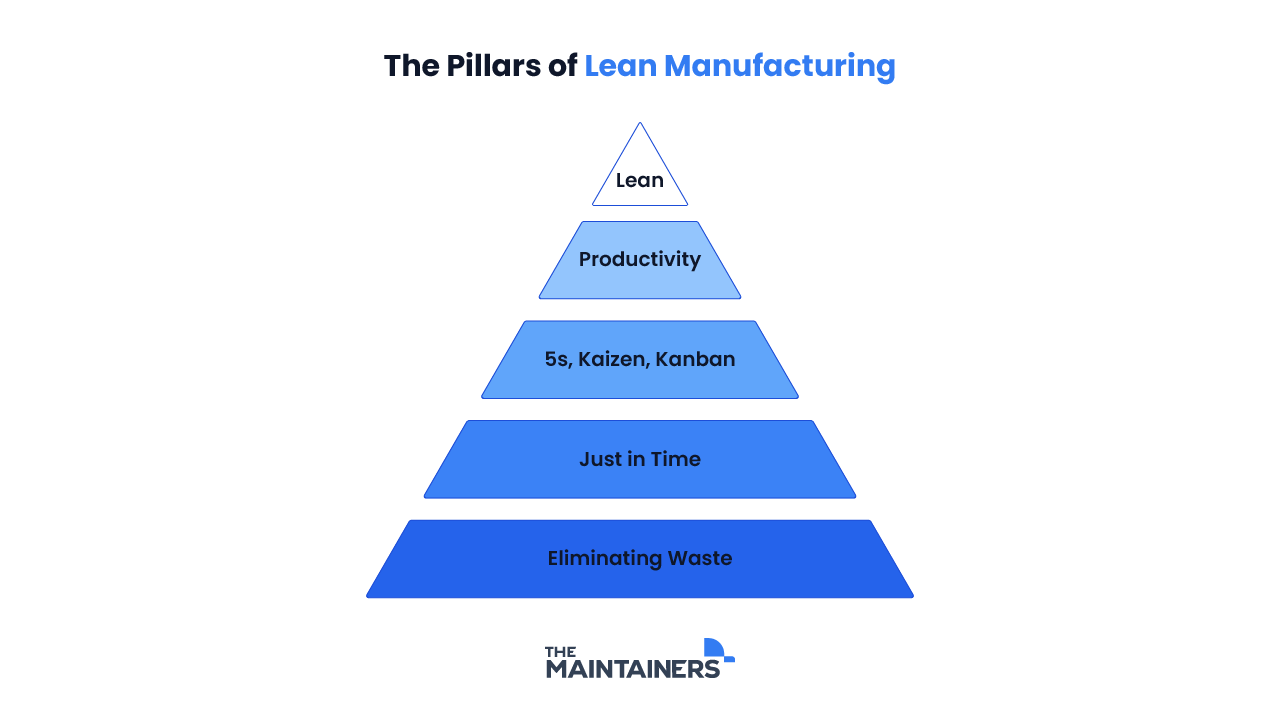

The lean methodology has five primary principles:

- Identify and eliminate waste: The first step in lean manufacturing is to identify all of the waste that is occurring in the manufacturing process. This waste can be in the form of excess inventory, overproduction, transportation, waiting, defects, and unused talent.

- The Value Stream: A value stream is a sequence of all the steps that are involved in producing a product or service. Lean manufacturing focuses on creating a value stream that is as efficient and streamlined as possible.

- Just-in-time (JIT) production/Flow: Products are only produced when they are needed. This helps to reduce inventory costs and improve product quality.

- Kanban/Pull System: Introduce pull between all steps where continuous flow is possible; maintenance activities are only performed when triggered by a customer signal or the next process in the value stream.

- Continuous improvement/Perfection: Move towards perfection so the number of steps and the amount of time and information needed to serve the customer continues to decrease, and productivity peaks.

Both lean manufacturing and maintenance put these philosophies into practice to minimize costs and increase the reliability of processes, equipment, and systems, and has the ultimate goal of continuous improvement and optimal productivity.

Types of Waste in Lean Manufacturing

“Waste” refers to any action or step in a process that does not add value to the customer; waste is any process that the customer does not want to pay for. The original TPS system outlined seven original “wastes”: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing and Defects. However in the 1990s, an eighth waste was added, Skills.

- Transportation: Waste in transport refers to the movement of assets, people, tools, or products further than necessary. Some countermeasures, particularly in the production line, include developing a U-shaped line to encourage flow between processes.

- Inventory: Inventory waste means having more inventory than necessary to sustain a steady flow of work. This can lead to problems including product defects, inefficient allocation of capital, and problems hidden away in inventory. Machinery related excess inventory can include non-functional machinery and extra material. Avoid inventory waste by purchasing raw materials only when needed and in the required quantity, reducing buffers between steps, and creating a queue system for inventory management.

- Motion: Waste in motion means the unnecessary movement of people, tools, assets, and products. Motion waste in manufacturing can include repetitive movements that do not add value such as reaching for materials, walking to collect a tool or other materials, and readjusting an already installed component.

- Waiting: Waste through waiting includes personnel waiting for tasks, machinery, or pieces of equipment, and machinery that is idling. Waiting periods are often caused by an imbalanced production process and can result in excess inventory/overproduction. Designing processes that ensure continuous flow and developing multi-skilled, flexible workers are two ways to counteract and reduce waiting time/waste.

- Overproduction: Much like inventory waste, overproduction waste refers to creating product beyond existing orders/being required. Overproduction can cause problems from preventing smooth flow of work to increased storage costs, missed defects, and excessive lead-time.

- Overprocessing: overprocessing refers to doing additional work, adding components, or having additional steps in a process than is necessary to provide the value desired by the customer. This includes overengineering solutions, making reports excessively detailed, and extra steps in workflow. A way to reduce overprocessing is to only produce work to the level and expectation of the customer, and only in the quantities required.

- Defects: Defects happen when a product is not fit for use, resulting in reworking or discarding the product. This is considered a waste as costs are increased yet do not have value to the customer. Countermeasures include identifying the most common defect and implementing a process that detects abnormalities before they enter the production process.

- Skills: This waste refers to the waste of human potential, creativity, and ingenuity. This often happens when manufacturing frontline workers are expected to follow orders instead of being asked to contribute with their direct knowledge and expertise. It is also evident when workers are poorly trained, unable to operate equipment, and not challenged to improve work.

So… What is Lean Maintenance?

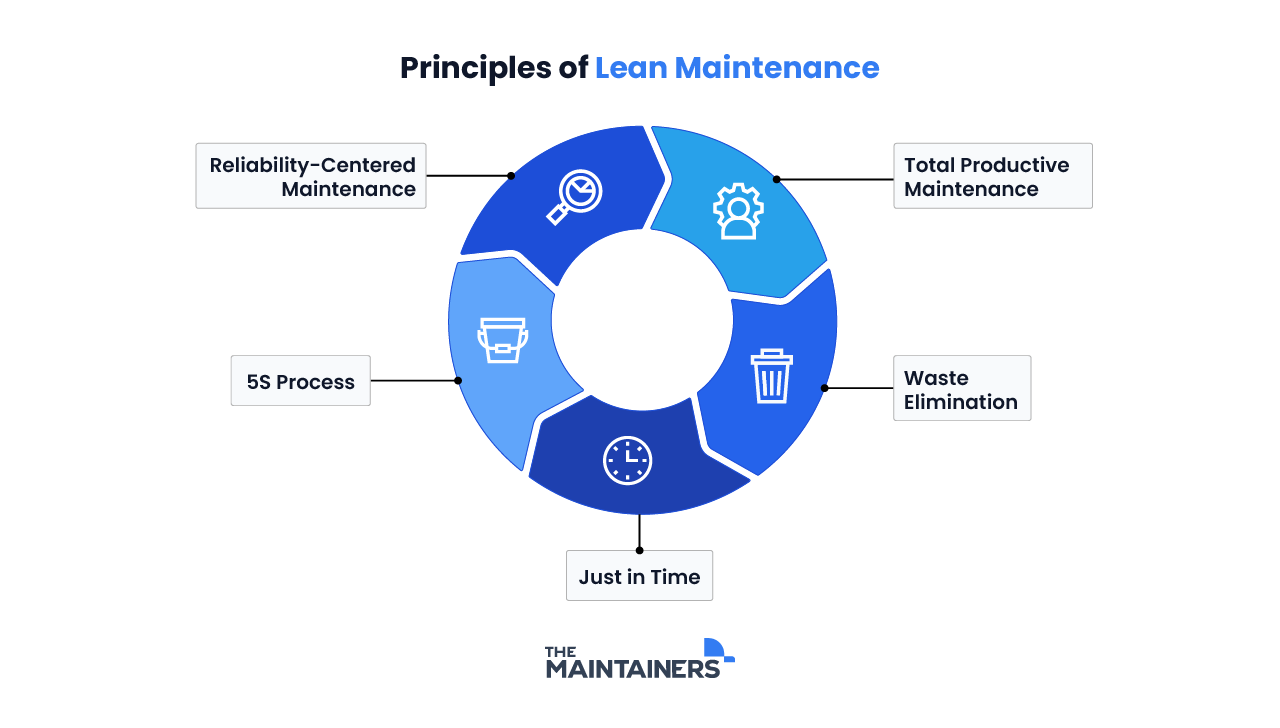

Lean maintenance effectively takes the principles of lean manufacturing and applies it to a maintenance operation. While lean manufacturing focuses on the elimination of waste from the manufacturing process, lean maintenance is focused on eliminating waste from the maintenance process. This can involve a variety of activities, such as improving preventive maintenance practices, reducing downtime, and extending the life of assets.

Lean maintenance strategies can be applied to all types of equipment and systems, in all industries. It is a powerful tool that can help organizations to improve their maintenance operations and achieve their business goals. The eight wastes that apply to manufacturing also apply to the maintenance department and directly affect reliability. The lean methodology especially highlights overprocessing as a wasteful activity, with unnecessary effort and process costing money without adding value. Over-maintenance of equipment—such as checking on assets when there’s no known problem, or simply because it’s a periodically done task— has a financial cost, and introduces the risk of reliability issues through human error while impacting equipment availability. Preventive maintenance is a solution that reduce waste due to over processed maintenance routines.

Depending on the type of waste involved in the process, maintenance managers are advised to apply the concepts of lean manufacturing to improve the process in the most efficient way.

Here are some examples of how lean maintenance can be implemented in a real-world setting:

- Identification and elimination of “inventory waste”: A company could use a kanban system to ensure that only the necessary spare parts and materials are kept on hand.

- Development and implementation of preventive maintenance plans for critical equipment and systems: Companies can use condition-based monitoring tools to identify potential problems before they cause equipment failure. One such tool is TRACTIAN’s TracOS™, the maintenance & reliability management software that helps organizations of all sizes be more agile and predictable. Through Work Order Management, Inventory Control, Mobile Requests, and all sorts of asset management tools, the platform can be integrated with other ERPs and also works with TRACTIAN’s patented AI to assist maintenance managers in optimizing preventive maintenance processes, reducing costs, and eliminating waste.

- Improvement of work order management system: A company can utilize an enterprise asset management (EAM) system to track work orders and ensure that they are completed on time and within budget. Learn more about EAMs here.

Maintenance teams that implement the lean philosophy while using modern monitoring technologies play a big role in optimizing their maintenance program, improving equipment uptime, maintaining quality, and reducing unnecessary inventory. Through lean maintenance principles, organizations can reduce costs, improve reliability, and extend the life of their assets, leading to long term productivity and increased profitability.