When it comes to manufacturing and production, ensuring consistent production and minimal downtime is crucial. In order to guarantee this, maintenance managers need to ensure their plants, assets, and overall production operations are reliable.

What is Production Reliability?

In the most basic sense, production reliability measures the efficiency of individual machines and assets on the line and the total dependability of manufacturing processes.

A high production reliability means your assets are working at a dependable and consistent rate. Low production reliability on the other hand, means your production is unpredictable and inconsistent.

Implementing good maintenance practices are important to build this foundation of asset and production reliability, as even small problems with equipment can cause significant issues. A lack of proactive maintenance that tackles problems before they escalate leads to frequent machine and component breakdowns, which in turn reduces production quality and rates, increased downtime, and increased production costs. Optimizing your process and implementing data-driven maintenance strategies can increase production reliability scores, helping you establish a profitable and competitive production facility.

How to Calculate Production Reliability

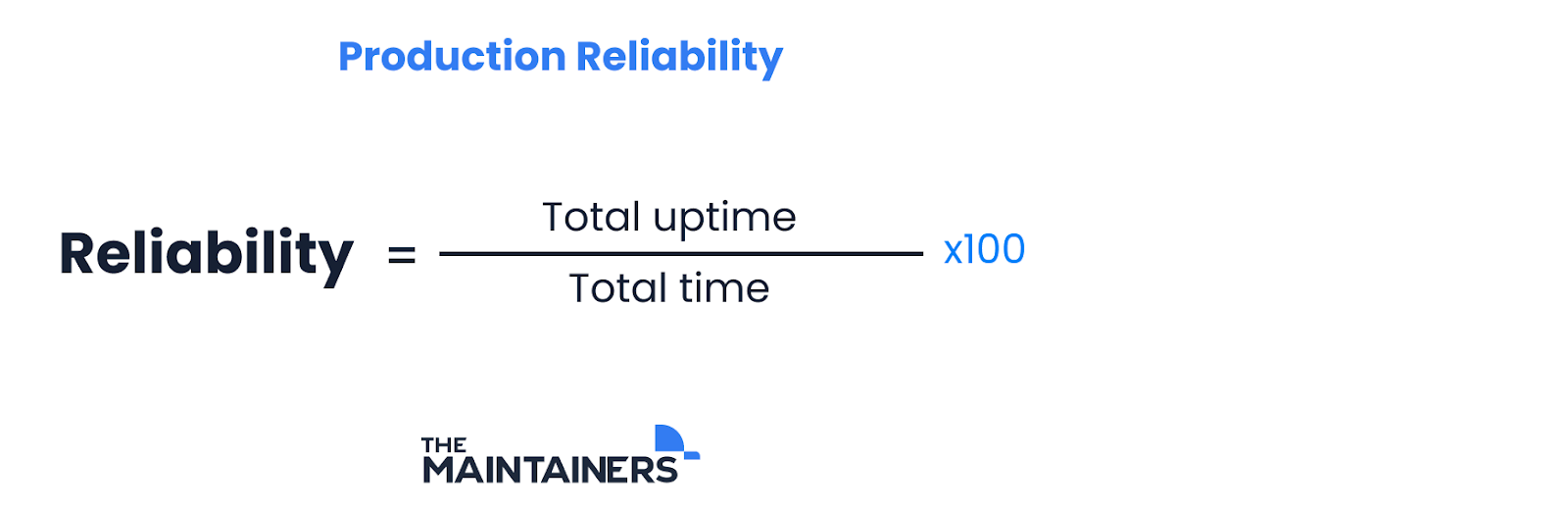

Production reliability is a measure of how consistently a system or process performs its intended function over a specific period. It is typically expressed as a percentage and is calculated using the following formula:

Here’s how you can break down the calculation.

Determine Uptime and Downtime:

| Uptime | Downtime |

| The total amount of time the system or process is operational and producing output. | The total amount of time the system or process is non-operational or experiencing issues that prevent it from producing output. |

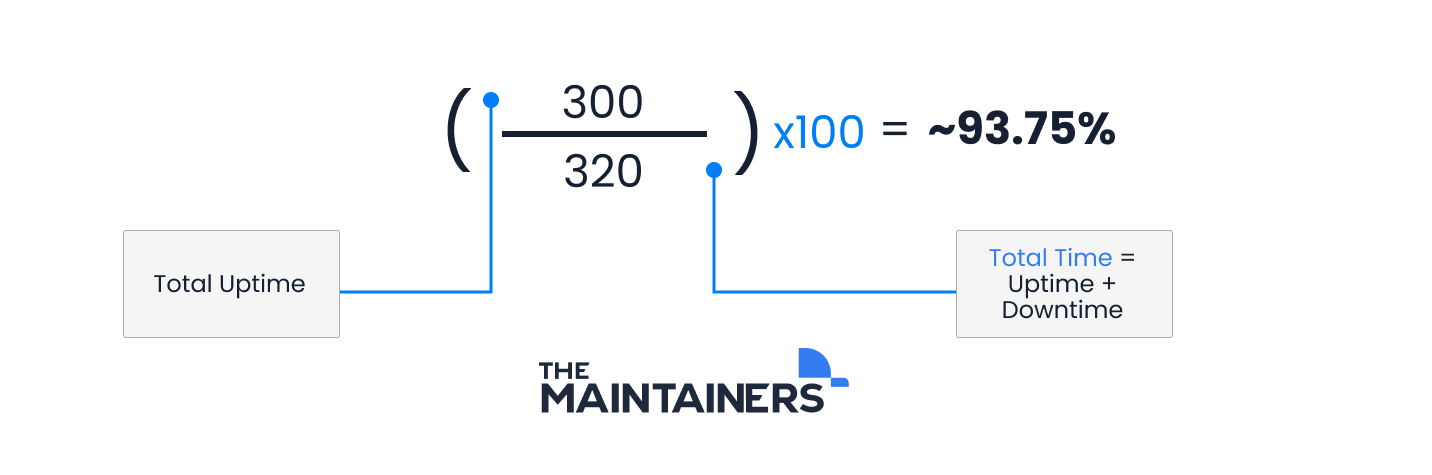

Total time is the sum of both uptime and downtime. And again, to calculate reliability, we would use the equation (uptime / total time) x 100%.

For example, let’s say a manufacturing system operates for 300 hours in a month and experiences 20 hours of downtime for maintenance and repairs. Using the formula:

Uptime = 300 hours

Downtime = 20 hours

Total Time = 300 hours + 20 hours = 320 hours

So, in this example, the production reliability of the system is approximately 93.75%.

This means that it operated at its intended capacity for about 93.75% of the total time.

You can also use other metrics to calculate your production reliability, namely overall equipment effectiveness (OEE), and overall production reliability (OPR).

OEE compares the real performance of assets against their ideal performance. It looks at an individual machine/system and calculates its equipment availability, performance, and quality, while OPR measures the dependability of your system as a whole. It calculates the OEE scores of all assets on the production floor and provides you with the average OEE for your entire facility.

Identifying bottlenecks in your process and system is crucial to understanding how to improve your production and equipment reliability. Monitoring and analyzing asset and team performance data and long-term performance allows you to tackle those bottlenecks and strategize continuous improvements.

Ways to Improve Production Reliability

Implement more strategic maintenance approaches.

Whether it be reliability-centered maintenance (RCM) to identify the most critical components and focus maintenance efforts on them, or preventive maintenance to identify and address potential issues before they lead to breakdowns or failures, or predictive maintenance to predict when equipment might fail through the use of advanced monitoring technologies and data analytics, focusing on failure elimination instead of only corrective measures makes your maintenance process more predictable, and thus your production.

Invest in a CMMS to automate your maintenance and track your performance.

Computerized Maintenance Management Systems, or CMMS, are software that can record and analyze your maintenance for you, instead of relying on outdated spreadsheets or manually recorded paperwork. In addition to this, many CMMS’ have the capacity to automate scheduling for maintenance and planned downtime, generate collaborative work orders, and to analyze KPIs such as team performance and costs. Having access to this real-time data and automated procedures helps you develop a strategy to improve process reliability.

TRACTIAN’s TracOS™ makes maintenance management easier than ever. Optimize your work order process with a fully digitized and collaborative platform, fully integrated with QR codes that let you see the complete history of an assets maintenance. As tasks are assigned and completed, you can access performance metrics like cost per work order, inventory used, task completion time, team efficiency, and so much more, so you can learn where your areas of improvement are with real-time, accurate data.

The TracOS™ platform learns your maintenance needs through work order history, and can plan and schedule the ideal preventive maintenance strategy for optimal asset performance.

Have an equipment redundancy plan.

Consider ways to back up and support critical assets. Developing protection systems allows production to continue even if there is equipment failure. Not only does this prevent production downtime, but also ensures you have the time to conduct failure analysis and find ways to prevent the issue reoccurring.

Implement condition monitoring tools.

As technology continues to progress, as do the tools available for maintenance teams. Condition monitoring tools such as IoT sensors can constantly monitor asset behavior, tracking elements like vibration and temperature, to provide you with a baseline for normal behavior, as well as identification of anomalies that may signal a problem, or potential failure.

Embrace Root Cause Analysis (RCA).

A good maintenance strategy focuses on eliminating the root causes of disruptions and recurrent equipment failures. RCA means you are identifying and eliminating the root cause of a problem, instead of just reactively correcting it every time.

By identifying the underlying causes of a problem, it is less likely to occur once it’s been solved. Not only does this minimize unplanned downtime and production stoppage, but it also extends your asset’s lifetime, reduces costs, and increases both efficiency and asset reliability.

Train your Team.

There is only so much you can do to improve your assets and equipment, and oftentimes your team plays the most significant role in boosting production reliability. Whether it’s training to upskill employees, internal reorganization, or fostering a new culture of reliability, making sure your team has the buy-in to improve your reliability is fundamental.

This is particularly true if you’re implementing new tools and procedures. Make sure your team has the capacity to appropriately understand and use new methods to maximize your ROI, and adjust your training to fill skill gaps as soon as they’re identified.

The Benefits of Improving Production Reliability

Working on your reliability can take significant effort and time, but the benefits are tenfold. There are major benefits that can make a visible impact on your process and production, such as:

Increased Productivity and Profits: Reliable production processes result in fewer disruptions and downtime, leading to higher levels of productivity and output. It leads to more consistent revenue streams and lower operational costs, ultimately improving the bottom line. Asset life spans increase with regular maintenance, delaying costly replacements.

Reduced Downtime and Costs: By minimizing unexpected breakdowns and maintenance, businesses can avoid costly downtime and emergency repairs. Inventory does not go to waste, and with enhanced quality control, less suboptimal/discarded product.

Improved Workplace Safety: Reliable equipment and processes are less likely to malfunction or pose safety risks to workers, creating a safer work environment. Employees that embrace a culture of reliability feel comfortable knowing they are not constantly fire-fighting unexpected problems or breakdowns.

Environmental and Regulatory Benefits: Reliability can lead to reduced waste and resource consumption, contributing to more sustainable and environmentally-friendly operations, and meeting production schedules and quality standards can help businesses comply with industry regulations and avoid penalties.

Improving your production and asset reliability is an effort that takes time and dedication, as well as investing in both your tools and your team. TracOS™ ensures that your team and your assets are working at their best and improves production and reliability, while decreasing unplanned downtime.